Titan XQ puls

Wishful thinking becomes reality.

That is exactly what you get with the Titan XQ puls from EWM: the latest RCC inverter technology and innovative EWM XQ welding processes included in your welding machine ex works and ready to use. Plus there are lots of other ways you can configure the Titan XQ puls to suit your needs.

Titan XQ puls – a series of perfection. Individually configurable casing design for more flexibility thanks to a wide range of options.

- Titan XQ puls decompactWith a wide range of options and accessories for the Drive XQ wire feeder, the 350 A, 400 A, 500 A and 600 A models (either gas or water cooled) can be adapted to all your requirements.

Welding Process

- rootArc® XQ/rootArc® puls XQ

- coldArc® XQ/coldArc® puls XQ

- forceArc® XQ/forceArc® puls XQ

- wiredArc XQ/wiredArc puls XQ

- acArc puls XQ

- Positionweld XQ

- TIG and MMA welding, gouging

- Pulse XQ/Standard XQ

Drive XQ wire feeder – great options to make life easier

Drive XQ wire feeder

At just 13 kg (excl. wire spool) and with a balanced, ergonomic handle, the Drive XQ wire feeder is the perfect companion for impassable scaffolding, hard-to-reach work spaces or large components – it can even fit through manholes.

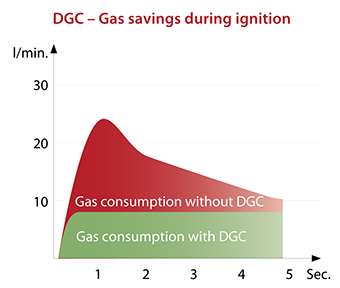

DGC – electronic gas flow control: save gas with ease and accuracy (optional)

- Prevents welding errors caused by too much or too little gas

- Efficiency through gas savings thanks to accurate settings

- Fully reproducible thanks to digital configuration and saving to the respective JOB (welding task)

- Constant gas flow rate thanks to electronic adjustment

- Nominal and actual value display of gas flow rate in l/min

- Extremely advantageous with long hose packages, e.g. for shipbuilding and steel construction

- No gas blast with turbulence when igniting the arc as electrical valve opens and closes gently

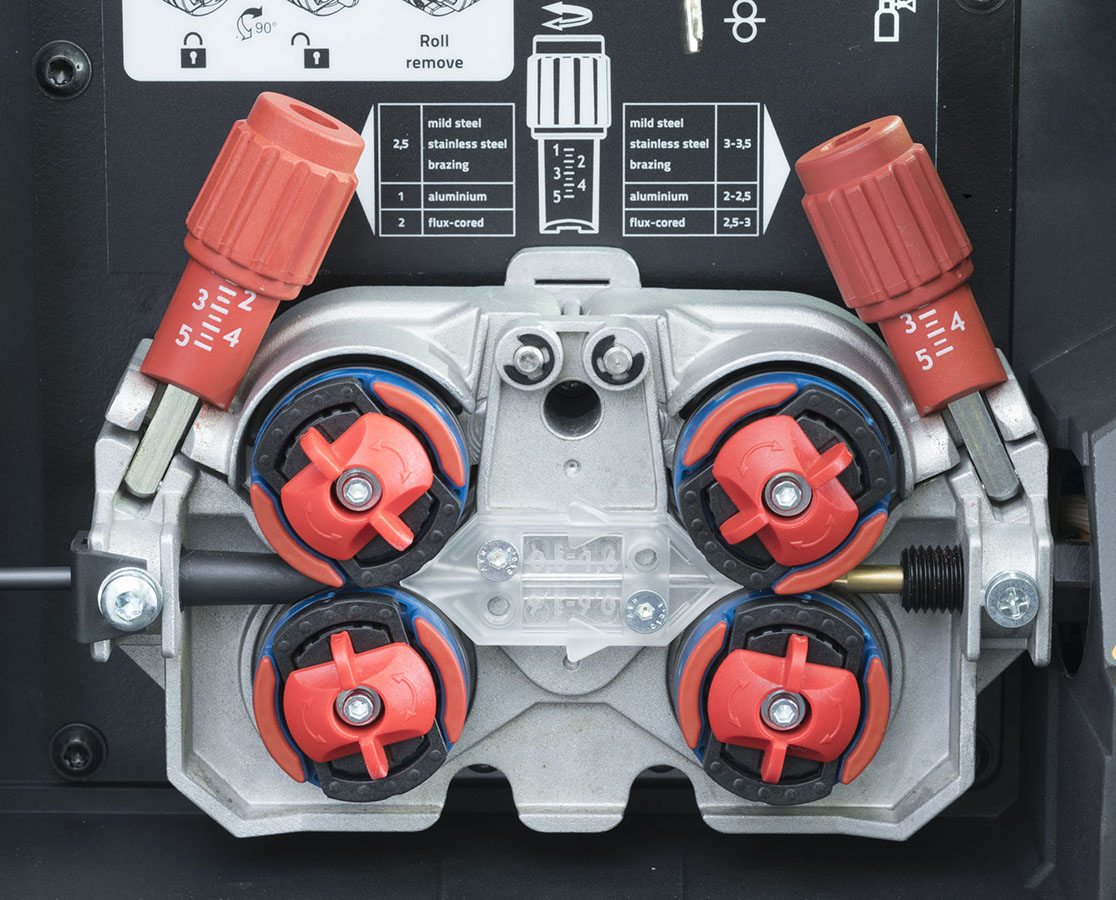

eFeed wire feeder – full traction

- eFeed wire feeder with ball bearings and four driven drive rolls – one more step forward

ewm Xnet 2.0 – Welding 4.0 for large and small businesses. The modular system supports both welding coordination personnel and welders in their daily work.

One Response