The refrigeration plants onboard oceangoing ships, regardless the type and size of the merchant vessel, are a crucial component in the overall aspects of the ship operations. Refrigeration is used in maintaining the required temperature for the rooms intended for vegetables, meat, fish as well for the general provisions. It is also used for airconditioning of the accomodations as well as the Bridge and Engine Control Rooms. Some cargoes require refrigeration to ensure that it maintains its condition from the port of origin to its destination. For example a Reefer Ship which transports perishable products like fish and fruits does not only have to be fast but requires refrigeration to prevent its cargo from spoiling.

Requirements for the Bachelor of Science in Marine Engineering(BSMarE)

In order to comply with the Revised Curriculum for Bachelor of Science in Marine Engineering (BSMarE) in compliance with CHED Memorandum Order # 67 series of 2017 and Annex C.2 of Joint CHED-MARINA Memorandum Circular No. 02, series of 2019, a Refrigeration Equipment is needed in order to be utilized for the following subjects in BSMarE course namely: Thermodynamics and Auxiliary Machinery 2. One such equipment that complies with this requirement is the Advanced Training Unit for Fault Location(Product 811) from PA Hilton.

Advanced Training Unit for Fault Location 811

The Advanced Training Unit for Fault Location 811 is a fully operational refrigeration unit with two visible evaporators simulating freezing and cooling rooms, operating from a single semi-hermetic condensing unit.

The unit is constructed entirely from standard commercial components, including all of the necessary primary and safety controls and will give students valuable experience of system adjustment and fault finding on a multi-evaporator three phase refrigeration system.

On the model 811 all standard components are visible, mounted on a steel frame with stainless steel panels. Instrumentation includes condensing, evaporating and suction pressures, mechanical and digital temperature measurement, digital multi-meter and optional refrigerant flow meters. The system includes reverse gas defrost, suction accumulator, oil separation and variable speed evaporator and condenser fans.

Instructor controlled faults are induced by internal components which are hidden from student view. A standard Student Tool Kit, and Test and Service Equipment Package are available as optional items.

Specifications:

Compressor: Semi-Hermetic, 0.37 kW. 1450 rpm

Condenser: Air-cooled, aluminium finned, copper coil

Evaporators: Display-case evaporators. Aluminium finned, copper coils with hot gas defrosting

Injection controls: 2 thermostatic expansion valves

Liquid receiver

Control equipment:

- Low and high-pressure control

- Thermostatic control

- Evaporator pressure control

- Capacity control

- Condensing pressure control and crankcase pressure control

- Low pressure switch

- High pressure switch

- Measuring equipment: Digital temperature indicator with 10 ways elector switch

- 4 pressure gauges (3 compound,1 high pressure)

- 2 dial thermometers.

- Hand-held digital multi-meter

- 25 switches located on the side panel under a hinged cover allow combinations of faults to be activated by the instructor.

- An electrical control box is mounted on the panel and includes accessible three phase relays, fuses and an overload protector. An internal three phase residual current device protects against earth leakage. Fan speed controls and defrost switch with indicator are also panel mounted.

Based on its capability, the equipment can be used for both training and assessment and can be utilized not only for Maritime Higher Education Institutions(MHEIs) but for Maritime Training Institutions(MTIs) as well.

Why use PA Hilton?

PA Hilton is in collaboration with some of the world’s leading higher education institutions. As a British manufacturer they are proud that teaching institutions from the USA to India and beyond benefit from PA Hilton’s renowned catalogue of high-quality engineering teaching equipment. Recently they have visited the British Colombia Institute of Technology (BCIT) in Vancouver and met with representatives of vocational centre (HVAC), Mechanical Engineering Department and Power Engineering Department to talk to them about our work and products and was delighted to add BCIT to the thousands of education centres that use PA Hilton teaching equipment.

References:

- Loading of Provision

- PA Hilton, Advanced Training Unit for Fault Location -25 Faults

- Repair and Maintenance of Reefer Containers(Image)

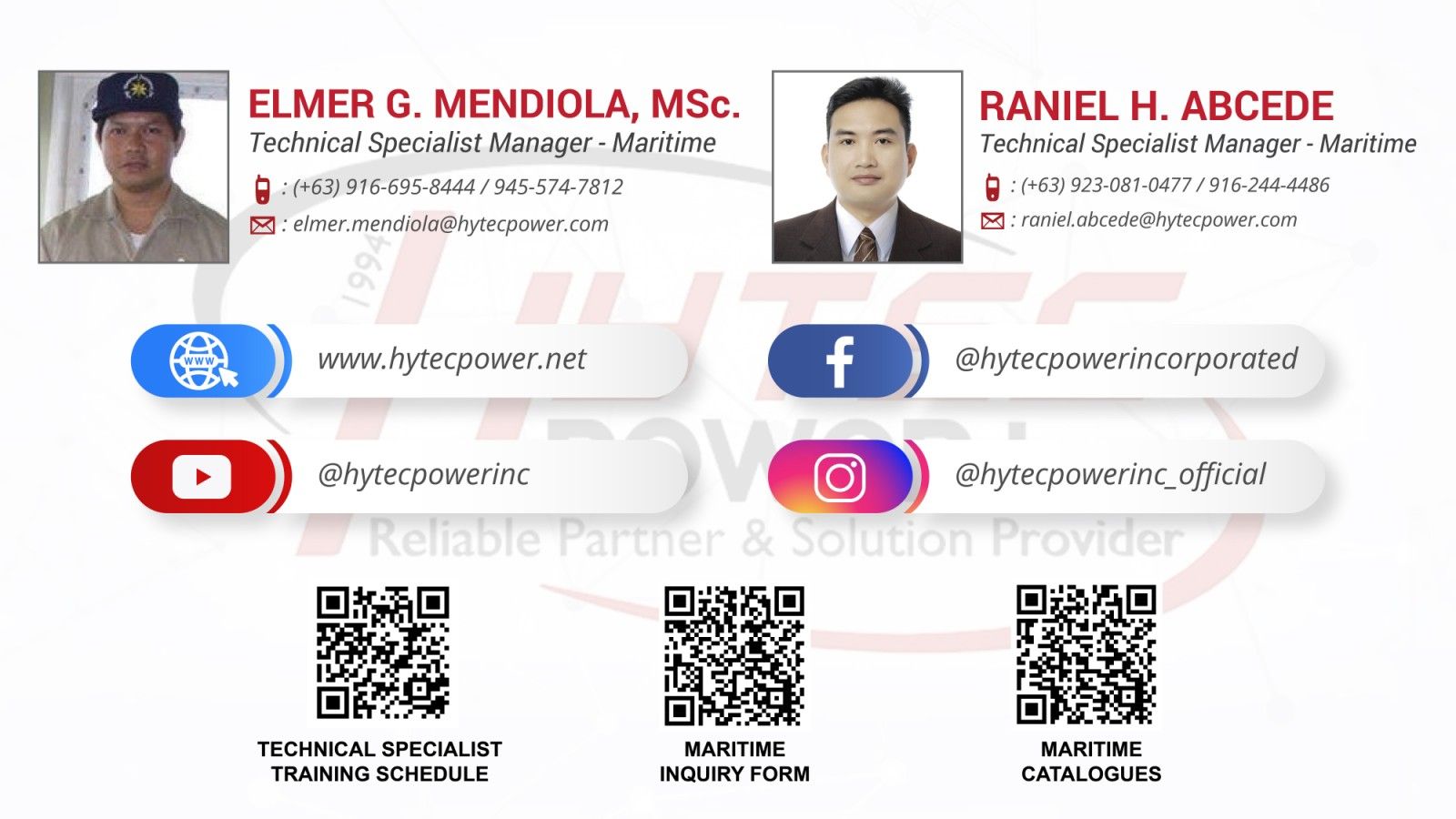

Contact us