As the digitalization revolution continues to sweep across a broad range of industry sectors, industrial bolting is no exception. Businesses have no option but to become more efficient through the use of modern digital technologies. Any that resist, do so at their peril as they will undoubtedly be left behind.

Take a look to a revolutionary process control and data collection system for industrial bolting operations.

COMMANDER XT2000

Best in Class, Patented, Joint Integrity Process Handheld Control Data Collector

- Rugged IP65 Handheld (Class 1 Div 2)

- Real time data collection

- Unlimited, user-defined traceability

- Flexible user management and operating modes

- User defined bolt pattern management per ASME PCC-1-2013

- Password enabled roles and privileges

- Multiple interface potential—leak detectors, calipers, hydrostatic test, flow meters, ultrasonic

- Configurable out of tolerance alerts

- Non-editable data (what you see is what you get)

- Ability to change tools from bolt to bolt or from pass to pass

- Supervisor required overrides option for non-conforming data

- Management notifications by email or text

- Adaptable to ANY hydraulic pump (AC or air) using ANY hydraulic torque wrench

- Wirelessly controls any pump from up to 80 feet away in as few as 5 seconds

- Precision control of the pump without violating the manufacturer’s warranty

- Connectivity via 2.4 GHz Bluetooth or tethered

- AC and/or battery operated Control Module with 3 week’s life

- Indicator lights on Control Module to show battery status

- Digital control to within .05% accuracy vs. 2-3% with analog

- Removes the possibility of over or under torqueing

- Saves time in constant pump adjustments

- Could eliminate the need for explosion proof certification due to proximity from application

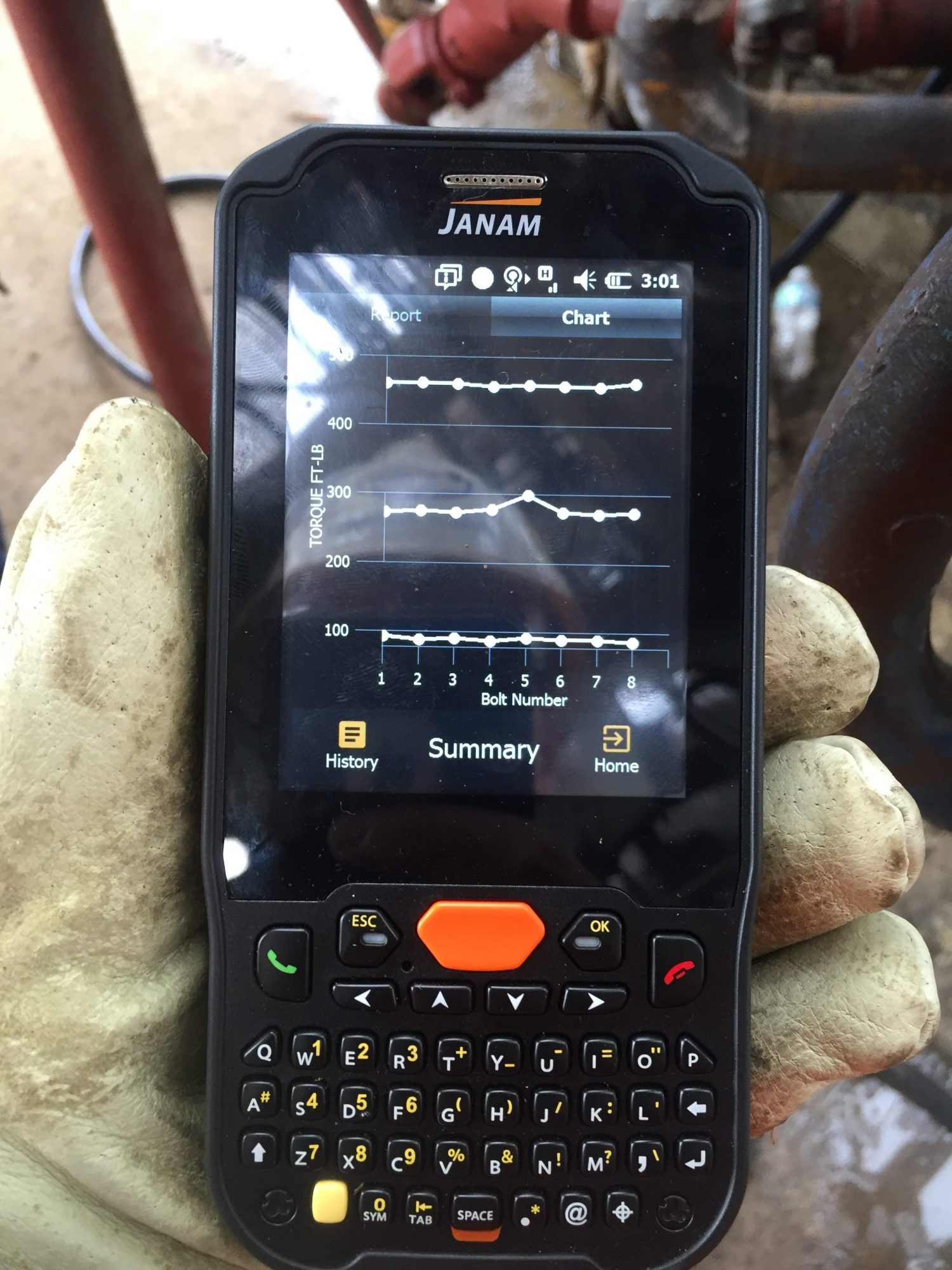

The Torq-Comm Commander XT records the torque applied to each and every bolt individually, and stores the data on cloud based software, bolt by bolt.

Torq-Comm Integrates With RAD Gun

Torq-Comm has added pneumatic torque multipliers to its data logging and Process QA system. The system is now capable of logging the data on any model Pneumatic Torque Wrench.

Torq-Comm has added pneumatic torque multipliers to its data logging and Process QA system. The system is now capable of logging the data on any model Pneumatic Torque Wrench, from manufacturers such as New World (RAD), Norbar, Atlas Copco RTP series, Bolttech Mannings, Norbar and more.

Additionally the system will ensure the bolting process is done properly in the correct sequence and in the appropriate number of passes and check passes.

For inquiries contact Hytec Power Inc. PH Distributor

If you would like to discuss these products further, or how they can benefit your application, then please do give us a call.