Before the Oil Crisis in 1974, majority of oceangoing ships utilizes a Main Boiler for its steam source. One such type of ship is an Oil Tanker which uses a Steam Turbine for its propulsion while the flue gas is processed and used to inert the oil tanks thereby preventing an explosion during cargo operations. But after the Oil Crisis, steam propulsion gave way to diesel propulsion because the latter consumes less fuel and its efficiency was improved because of some modifications such as utilizing the waste heat to produce freshwater out of seawater and steam production using the economizer. That is the reason why most of the oceangoing ships today, is using an Auxiliary Boiler instead of the massive Main Steam Boilers to heat oil tanks, heating during winter time and for cooking food in the galley to name a few.

Requirements for the Bachelor of Science in Marine Engineering(BSMarE)

In order to comply with the Revised Curriculum for Bachelor of Science in Marine Engineering (BSMarE) in compliance with CHED Memorandum Order # 67 series of 2017 and Annex C.2 of Joint CHED-MARINA Memorandum Circular No. 02, series of 2019, an Operational and Functional Boiler is needed in order to be utilized for the following subject in BSMarE course namely: Power Plant 2- STEAM PLANT. One such equipment that complies with this requirement is the COMPACT STEAM TURBINE POWER PLANT from ESSOM.

136+ COMPACT STEAM TURBINE POWER PLANT, 1.5 kW

GENERAL DESCRIPTION

The unit is designed to simulate modern steam power plant. Main components consist of a feed water system, a small industrial boiler, a steam turbine, a generator and lamp load, a condenser with a condensate tank and a pump, and a cooling tower. Accessories such as fuel tank, fuel flow meter, feed water meter, and a stack are also included. Instruments are provided for measurement of pressures, temperatures, output voltage and currents.

TYPICAL EXPERIMENTS

- Measurement of feed water and fuel flow rates.

- Boiler efficiency, turbine generator efficiency, and overall power plant efficiency.

- Condenser heat transfer efficiency.

- Cooling tower efficiency.

- Rankine cycle efficiency.

TECHNICAL DATA

Boiler Unit:

| Type | Vertical, water tube. |

| Rated heat output | 125 kW (107,000 kcal/h) |

| Equivalent evaporation | Approx 200 kg/h steam at 0 kg/cm2 gauge. |

| Maximum working pressure | 10 kg/cm2 (0.98 MPa) |

| Measuring instruments: | -Pressure gauge for steam outlet. -Temperatures for feed water, boiler outlet, pressure regulator inlet, and exhaust stack.(including ambient temperature) |

| Safety devices | – Safety valve – Low level alarm – Level gauge and switch |

| Boiler accessories | – Steam separator – Steam pressure regulator – Feed water pump – Stack, 6 m stainless steel with elbows |

TECHNICAL DATA

Burner:

| Type | Forced draft, pressure atomized |

| Control | On-Off |

| Fuel | Diesel or kerosene. (LPG is available as an option.) |

| Fuel system | Stainless steel fuel tank, fuel strainer and fuel meter |

Feed water system:

| Resin filter for public water | |

| Stainless steel soft water tank | |

| Water meter | |

| Power supply | 380V. 3Ph. 50Hz Other power supply is available on request |

TECHNICAL DATA

Single-Stage Industrial Steam Turbine

| Description | This is an educational unit steam turbine with measuring instruments and synchronous belt for driving the generator. |

| Technical data | |

| Type | Single stage, twin nozzle impulse turbine |

| Construction | – Vacuum cast inconel wheel – Stainless steel casing shaft and nozzle |

| Maximum mechanical output | Up to 1.5 kW with superheated steam (optional) |

| Maximum speed | Approx 33,000 rpm |

| Exhaust pressure | Atmospheric |

Generator and Lamp Load

| Measuring instruments |

| Generator speed, voltage and current digital display |

Steam is generated by the small industrial boiler and drives a steam turbine which can connected to either a generator or a Water Brake Absorber Dynamometer. The dynamometer is connected to the turbine for measurement of mechanical output. Speed and torque sensors and indicators are provided. The unit is compact yet fully functional steam system just like the one utilized onboard oceangoing ships.

Why use ESSOM Products?

Quality assurance

ESSOM has been certified ISO 9001 Quality Management System since 1999. The scope of certification includes Design and Manufacturing of engineering equipment as well as Sales and Service of both engineering education and paint spray equipment. All the engineering education products have been designed by their experienced and well qualified engineers. Prototypes must pass design test standards before market introduction. Parts and materials are sourced from approved supplier/material lists and must pass receipt inspection. In-process inspection is carried out at key manufacturing stages with final inspection after completion. All new products must pass strike design test before market introduction.

Market

With ESSOMs global marketing network of agents and sales partners they have now supplied their equipments to over 50 countries.

References:

- ESSOM

- marine auxiliary boiler/Machinery, Tools and supplies/Apparel & Accessories

- Products: Auxiliary Boilers I Mitsubishi Heavy Industries Marine Machinery & Equipment Co. Ltd.

- 1.Z BOILER(MARINE AUXILIARY BOILER)

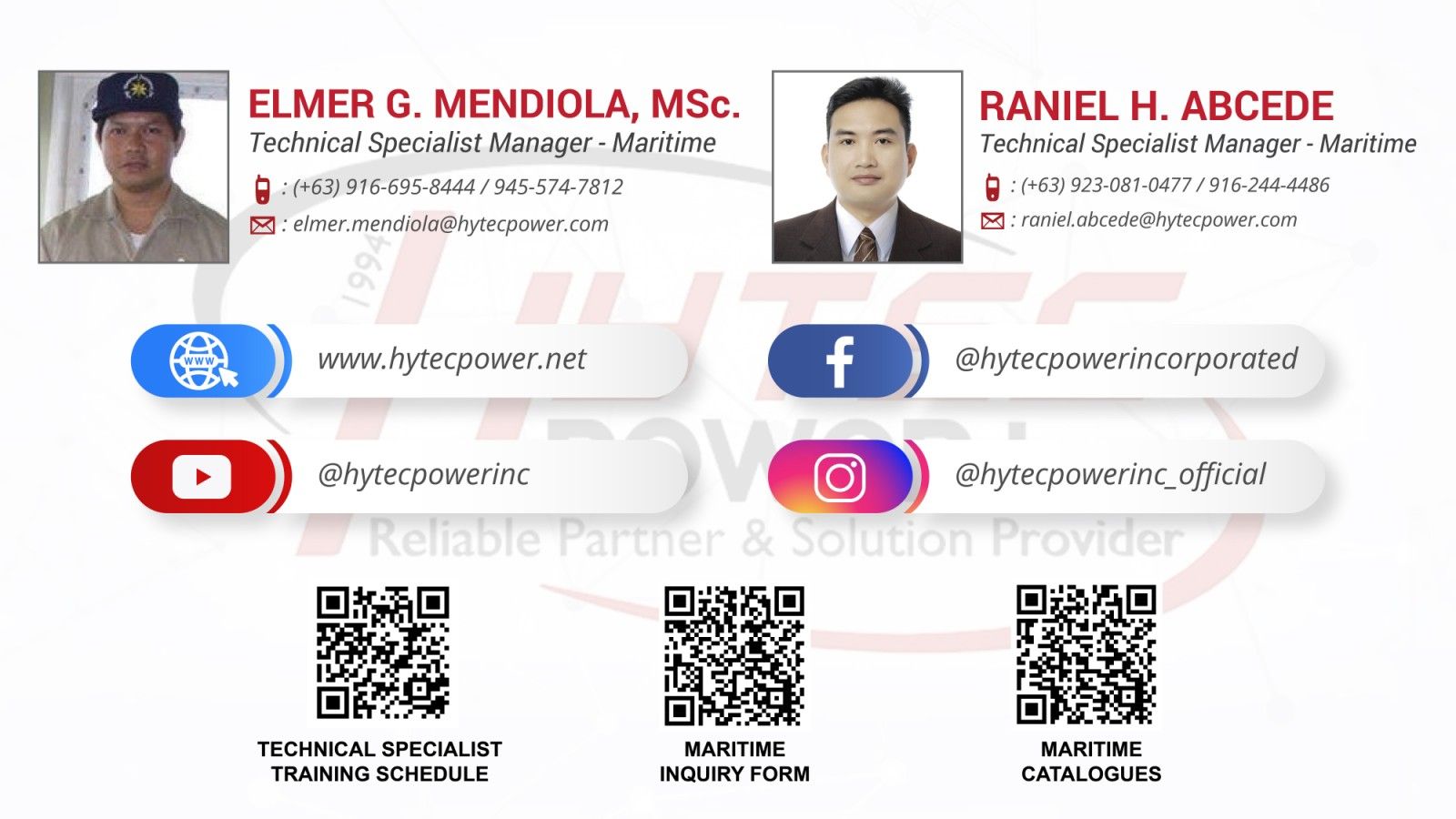

Contact us